|

|

🏦 Shrinkable Film for Banknote or Coin Tube

Packaging

Engineered

for High Quality. Trusted Worldwide.

KINGTON provides professional-grade shrink film designed for

secure and efficient cash packaging. Our film is widely used in cash

centers, banks, and currency-handling environments for bundling

banknotes, coin tubes, and related

packaging units. With stable shrink performance and clean sealing

results, it helps improve packaging efficiency while maintaining a neat,

tamper-evident presentation.

🔧 Key Applications

-

Banknote bundle wrapping and sealing

-

Coin tube outer shrink wrapping

-

Cash center / bank back-office packaging

workflows

-

High-volume packing environments

requiring consistent sealing performance

🔧

Product Highlights

-

Material Options: LDPE, Polyolefin

(POF), or Polypropylene – transparent, biaxially oriented

-

Form:

Flat Foil or Half-Tube

-

Compliance: Meets ECB and U.S. Federal Reserve standards; MSDS

certified

-

Compatibility: CPS 600, DLR 6000

Suitable for high-speed banknote processing and packaging systems commonly

used in cash centers and banking environments.

-

Application: Banknotes, Coin Tubes,

Cards, Coupons, Labels, Pharma packaging

-

Advantage: Seamless (joint-free)

construction. Smooth and consistent feed. Reliable high-speed shink wrapping,

Competitive pricing & fast lead time.

🔧 Customization Options

|

Compatible with |

Cash Processing Machines &

Coin Wrapping Systems |

|

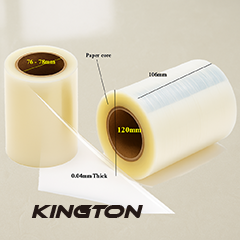

Tape Thickness |

15u, 19u, 25u, 32u, 40u, 82u, 90u,

100u, 110u, etc. |

|

Tape Width Options |

29, 38, 66, 80, 88, 106, 305, 355mm,

etc. |

|

Tape

Length Options |

100,

120, 140, 400, 800, 886 ,1067, 1454m, etc. |

|

Core Sizes |

40 mm, 50 mm, 76 mm (custom sizes available) |

|

Core Material |

Paper Core or Plastic Core |

|

Sealing Temperature |

Low-temperature or High-temperature sealable |

|

Pre-Printing |

Blank / Single-Color / Dual-Color / Custom Logo |

📦 Please check MOQ, lead time, and

pricing based on your specific requirements.

🎨

POF Shrink Film Options

🏭 Foil Film Wind Way

|

High rolls – 375 mm |

Refers to the height (or axial width) of the film

roll being

375 mm

when viewed standing vertically. This is likely the

film

roll width along the core axis. |

|

View from cut side |

This is the

cross-sectional (side) view of the roll after it’s been

cut—used to determine the direction of film winding and weld seam

orientation. |

|

Wind should allow weld from right side |

When you face the

cut

(side) of the roll, the

seam

(or weld) should be on the right. This instruction defines how

the film should be wound on the core. |

|

Foil is unreeling from oneself and from up |

When using the roll, the film should unroll

away

from the operator (toward the machine) and

from

the top of the roll, not underneath. This is to ensure correct

orientation and feeding into packaging machines. |

🏭

Applications

-

Central Banks

-

Cash-in-Transit (CIT) Companies

-

Commercial Bank Cash Centers

-

Currency Sorting & Processing Machine

Users

OEM Banknote or Coin Wrapping Equipment

Shrink Film for high-speed

banknote processing and packaging systems commonly used in cash centers and

banking environments.

Advanced Shrink Packaging for High-Speed

Currency Processing

Model: KT40-88140, KT40-106120.

Designed for use in

high-speed

banknote processing and packaging systems, these shrink film rolls are

engineered to deliver stable feeding, uniform shrinking, and consistent bundle

integrity. They are suitable for

advanced

banknote bundling and packaging platforms commonly deployed in central banks and

cash centers worldwide, ensuring reliable performance in demanding,

high-volume cash handling environments.

Manufactured from high-clarity

LDPE or POF

shrinkable foil, these films offer secure, tamper-evident packaging

through

automated L-sealer and tunnel modules. They deliver smooth feeding,

excellent shrink behavior, and reliable sealing—meeting ECB and U.S. Federal

Reserve standards.

♻️

Sustainability Advantage:

✔️ Precision Fit for

High-Speed Bundling Systems

Designed for seamless use with modern banknote and coin-tube bundling modules.

The shrink film delivers clean sealing and uniform conformity around bundles,

supporting efficient shrink-wrapping with minimal machine interruption.

✔️

High-Speed Shrink Performance

Engineered to withstand high-throughput operations (up to 120,000 notes/hour),

the film shrinks evenly without edge curling or film burn, ensuring consistent

bundle appearance and integrity.

✔️

Secure and Tamper-Evident

Once shrink-wrapped, bundles are sealed tightly to prevent unauthorized opening.

Optional internal label insertion supports traceability (e.g., operator name,

date, denomination).

✔️

Automation Ready

Fully compatible with automated loading, tracking, and cash-center management

systems, enabling a traceable, digitized, and efficient packaging workflow in

high-volume environments.

✔️

Eco-Conscious

Optimized to reduce energy consumption in shrink tunnels and minimize material

waste. Smooth, jam-free feeding improves operational efficiency while supporting

sustainability objectives in modern cash handling facilities.

♻️ Environmental

Commitment

Our packaging films are designed to support

sustainable, high-efficiency cash handling operations by enabling:

-

Longer machine lifecycle

-

Reduced replacement frequency

-

Lower energy and material consumption

-

Compatibility with

Eco-Remote and

Eco-Protect digital

services for remote diagnostics and secure updates

|

Compatible |

Thickness |

Width |

Length / O.D. |

Form |

|

B 500 |

19 Ám |

355 mm |

1000 m |

Half Tube |

|

B 500 |

40 Ám |

88 mm |

140 m |

Flat Foil |

|

B 1000 |

32-40 Ám |

355 mm |

O.D.254 mm |

Half Tube |

|

B 1000 |

40 Ám |

88 mm |

140 m |

Flat Foil |

|

B 2000 |

19 Ám |

355 mm |

1000 m |

Half Tube |

|

B 2000 |

40 Ám |

88 mm |

140 m |

Flat Foil |

|

B M5 |

40 Ám |

106 mm |

O.D.140 mm |

Flat Foil |

|

B

M7 |

40 Ám |

88 mm |

O.D.120 mm |

Flat Foil |

|

CPS 600 |

50 Ám |

300 mm |

500 m |

Half Tube |

|

CPS 600 |

110 Ám |

29 mm |

1000 m |

Flat Foil |

|

DLR 6000 |

19 Ám |

450 mm |

1000 m |

Half Tube |

|

DLR 6000 |

110 Ám |

47 mm |

950 m |

Flat Foil |

Types of film used

- Numerous polyolefin films with a standard thickness of 19 to 25 μm

- Film thicknesses of 15 to 50 μm are possible under certain conditions

|