Vacuum Wrapping Solution for Maximum

Security and Efficiency

At

Kington Co.,

Ltd., we’re committed to helping financial institutions, cash handlers,

and businesses across industries boost efficiency, security, and productivity

through innovative packaging solutions. Our

KT-610 Series

Banknote Vacuum Wrapper is the perfect example—designed to meet the

highest standards of safety, reliability, and performance.

Why Choose KINGTON KT-610?

✅ Maximum Capacity: Equipped

with the largest pump size, the KT-610 handles larger banknote bundles

effortlessly, reducing processing time and boosting throughput.

✅ Precision Control:

Programmable vacuum and sealing settings allow for quick, consistent

packaging—no guesswork, just repeatable results.

✅ Enhanced Security:

Vacuum-sealed tamper-evident pouches protect against moisture, contamination,

and unauthorized access. Optional embossing of source code or operator

information adds traceability and accountability.

✅ International Safety Certified:

Certified with TÜV and

CE marks, ensuring compliance

with stringent global safety standards.

Versatile Applications

The KT-610 goes beyond currency:

-

💰

Financial Sector:

Cash-in-transit companies, central banks, and commercial banks

-

🏭

Industrial Packaging:

Metal parts, bearings, coin tubes, welding rods, electronic components

-

🍱

Food & Beverage: Cheese,

seafood, dried fruits, ready-to-eat meals, tea, spices

-

💊

Pharmaceuticals & Medical Devices:

Hygienic, contamination-free packaging

-

📄

Archival & Long-Term Storage:

Important documents, sensitive chemicals, powders

Whether you need to protect cash, food,

electronics, or sensitive products, the KT-610 delivers professional-grade

vacuum packaging every time.

Banknote Vacuum Packaging

vs. Traditional Banding

Unlike traditional banding or strapping,

vacuum packaging offers:

✔ Superior moisture and dust protection

✔ Tamper-evident security

✔ Long-term storage readiness

✔ Clean, professional appearance

✔ Optional labeling for audit trail and traceability

At

KINGTON,

we don’t just sell machines—we deliver smarter, safer, and more efficient

solutions designed for the demands of a changing world.

Let’s grow

together. Contact us today to learn more about how the

KT-610 Series

and our other innovative systems can enhance your operations.

Technical Specification:

|

Chamber Dimension |

400 (L) x 320 (D) x 100 (H) mm |

|

Sealing Length |

Length 300 mm × Width 8mm |

|

Vacuum Pump |

Air Pump: 0.24kw ~ 6m³/hr ; Oil

Pump: 0.37kw ~ 7.2m³/hr |

|

Packaging capacity |

ca.2-3/min.

Number of packages: 1 |

|

Vacuum Pouches |

Polyethylene (PE) L20xW30cm; Thickness: 80μ (Option) |

|

Machine Dimension |

500 (L) x 366 (W) x 380 (H) mm |

|

Weight |

N.W. 40kg ; G.W. 45kg |

|

Power Supply |

AC 110V/60Hz or 230V/50Hz (universal model) |

|

Electrical Power |

Air Pump: 0.24kw ; Oil Pump:

0.3kw |

|

Optional Device |

Manual Press Assistance Device, Variable Size of Pouch |

A new standard

in banknote processing! The NotaPack banknote packaging system was developed

for Giesecke & Devrient’s (G&D) BPS® 1000, BPS® M7, BPS® 2000, and BPS® 3000

banknote processing systems. It fulfills strict requirements for banknote

packing, offering numerous advantages. The NotaPack packaging system offers

security and reliability throughout the entire

packing process. After the banknotes have been sorted by the BPS® machine, they

are assembled into packages and sealed in tamperproof film to complete the

process. The individual bundles are shrink wrapped. A label can optionally be

applied inside each bundle to record information such as value, name of

operator, machine number, and date of processing. This allows bundles to be

traced back to their source if necessary. One advantage of the fully automatic

process is a considerable

reduction in expenses for security personnel and surveillance equipment.

|

Applicable Model |

BPS1000 |

|

Plastic Material |

POLYETHELENE (PE) |

|

Shrinking Temperature |

180℃FCF

|

|

Plastic Foil Thickness |

32 micron |

|

Length |

1250 m |

|

Width |

355 mm, open 710 mm |

|

Outer Diameter |

254 mm |

|

Internal Diameter |

75 mm |

|

Core Thickness |

14 mm Paper Core |

|

Optional |

Customer Printing |

NotaPack consists of up to three

modules: two modules – a conveyor belt and L-sealer system with a shrink-wrap

tunnel – for the standard version, plus an optional label printer.

Module 1: Conveyor belt. The

bundles generated by the BPS are transported along the conveyor belt through a

tamperproof casing to the packaging module. The belt can be tailored to the size

of the customer’s BPS and the height of the banknote output compartments. The

conveyor belt can be retracted to the side if operator needs to access the BPS

machine (e.g. to replenish bundler film). The bundles can also be inserted by

hand, with access secured by means of a key switch. The optional printer module

can be installed on the conveyor belt. It can be configured to print the

banknote value, denomination, processing data, or other information on a label

on the bundler film. Module 3: L-sealer with shrink-wrap tunnel The L-sealer

encloses the bundled banknotes in special

film. The plastic wrap protects the notes from moisture and soiling and prevents

bundles from being opened unnoticed. With the Peelwrap® option, users can easily

open bundles without scissors or tools. Because of the tunnel’s small dimensions

and thorough insulation, power consumption and heat emission are considerably

lower than that of conventional systems. That makes special heat ventilation or

more powerful air-conditioning unnecessary. Since NotaPack also requires very

little compressed air, it can be hooked up directly to the BPS machine’s

compressed air supply.

Types of film used

- Numerous polyolefin films with a standard thickness of 19 to 25 μm

- Film thicknesses of 15 to 50 μm are possible under certain conditions

- Packer has an integrated sprocket drum

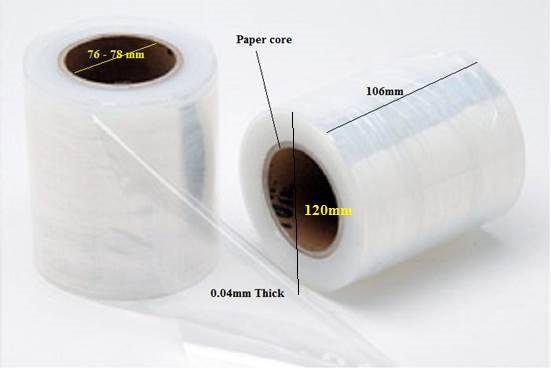

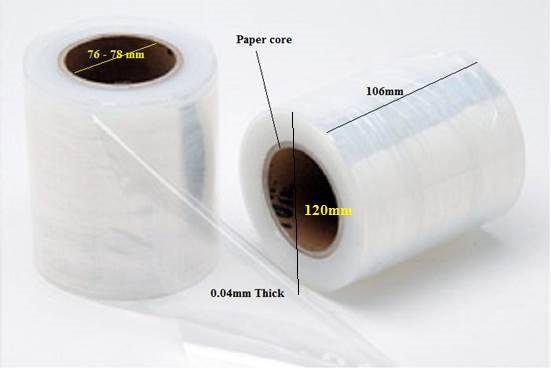

|

Applicable Model |

G&D M5 |

|

Plastic Material |

Flat Foil |

|

Plastic Foil Thickness |

40

micron |

|

Length |

140 m |

|

Width |

106 mm |

|

Outer Diameter |

120

mm |

|

Internal Diameter |

76-78 mm |

|

Core Thickness |

Paper

Core 5mm |

|

Optional |

Customer Printing |